QuikDrill Metal2Metal Specs

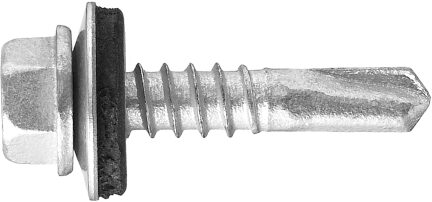

These self-drilling screws are ideal for light-to-medium gauge metal-to-metal applications. Our QuikDrill Metal2Metal drill points are designed to penetrate a wide variety of metal thicknesses. QuikDrill #3 points utilize a chisel flute that speeds up drilling time and eliminates point walking.

Metal2Metal

| Size | Head | Carton Qty | Weight/M |

|---|---|---|---|

| 12 x 1″ | 5/16″ HWH | 2500 | 12.21 lbs |

| 12 x 1-1/2″ | 5/16″ HWH | 2000 | 15.85 lbs |

| 12 x 2″ | 5/16″ HWH | 1500 | 19.15 lbs |

| 14 x 7/8″ | 5/16″ HWH | 2500 | 13.00 lbs |

*Not sold with sealing washer.

| Pull Out Strength (LBS ULT) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Material | ||||||||

| Designation | HRS Primed Only |

G-90 Galvanized |

||||||

| NOM. GAUGE | 16 | 14 | 12 | 22 | 18 | 16 | 14 | 12 |

| THICKNESS | .065 | .070 | .106 | .031 | .047 | .060 | .072 | .101 |

| #12 | 805 | 1128 | 1495 | 256 | 455 | 619 | 785 | 1446 |

| Point Diameter | Drill Point | Major Diameter | Minor Diameter | Head Across Flat | Washer Face Diameter |

|---|---|---|---|---|---|

| #12 | #3 | .209 / .215 | .157 / .165 | .305 / .310 | .440 / .460 |

| #14 Stitch | #1 | .240 / .246 | .185 / .192 | .306 / .312 | .396 / .432 |

| Pull Over Strength (LBS ULT) | ||||

|---|---|---|---|---|

| Material | ||||

| Designation | AZ55 Galvalume |

|||

| NOM. GAUGE | 26 | 24 | 22 | 20 |

| THICKNESS | .019 | .024 | .032 | .038 |

| #12 with 15mm Washer | 644 | 904 | 1144 | 1400 |

| Washer Sizes | Washer Sizes | Drilling Capacity |

|---|---|---|

| #12 OD | #14 Stitch OD | #12 |

| 15mm Bonded Washer | 14mm Bonded Washer | .035″ – .21″ |

| Size | Head | Carton Qty | Weight/M |

|---|---|---|---|

| 12 x 1″ | 5/16″ HWH | 2500 | 12.21 lbs |

| 12 x 1-1/2″ | 5/16″ HWH | 2000 | 15.85 lbs |

| 12 x 2″ | 5/16″ HWH | 1500 | 19.15 lbs |

| 14 x 7/8″ | 5/16″ HWH | 2500 | 13.00 lbs |

*Not sold with sealing washer.

| Pull Out Strength (LBS ULT) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Material | ||||||||

| Designation | HRS Primed Only |

G-90 Galvanized |

||||||

| NOM. GAUGE | 16 | 14 | 12 | 22 | 18 | 16 | 14 | 12 |

| THICKNESS | .065 | .070 | .106 | .031 | .047 | .060 | .072 | .101 |

| #12 | 805 | 1128 | 1495 | 256 | 455 | 619 | 785 | 1446 |

| Point Diameter | Drill Point | Major Diameter | Minor Diameter | Head Across Flat | Washer Face Diameter |

|---|---|---|---|---|---|

| #12 | #3 | .209 / .215 | .157 / .165 | .305 / .310 | .440 / .460 |

| #14 Stitch | #1 | .240 / .246 | .185 / .192 | .306 / .312 | .396 / .432 |

| Pull Over Strength (LBS ULT) | ||||

|---|---|---|---|---|

| Material | ||||

| Designation | AZ55 Galvalume |

|||

| NOM. GAUGE | 26 | 24 | 22 | 20 |

| THICKNESS | .019 | .024 | .032 | .038 |

| #12 with 15mm Washer | 644 | 904 | 1144 | 1400 |

| Washer Sizes | Washer Sizes | Drilling Capacity |

|---|---|---|

| #12 OD | #14 Stitch OD | #12 |

| 15mm Bonded Washer | 14mm Bonded Washer | .035″ – .21″ |

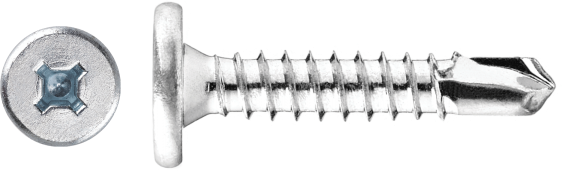

Clipscrews

Metal2Metal

QuikDrill Metal2Metal ClipScrews Specs

Our QuikDrill

Metal2Metal ClipScrews are designed to attach standing-seam roof clips to

steel purlins or frames. The special low-profile design features pancake

heads and a deep thread that pulls the fastener tighter and resists pull

out. As a result, you won’t get the dimpled roof panels and loose panel

problems typically caused by regular profile heads that don’t fasten tight.

Like all Marco ClipScrews, our QuikDrill Metal2Metal ClipScrews come

standard with 8-micron electroplating for exceptional lubricity, wear

resistance, and excellent durability.

| Size | Head | Carton Qty | Weight/M |

|---|---|---|---|

| 10 x 1″ | #2 Phillips Square Pancake | 5000 | 7.38 |

| 10 x 1-1/2″ | #2 Phillips SquarePancake | 2500 | 10.03 |

| 10 x 2″ | #2 Phillips SquarePancake | 2000 | 15.45 |

| Point Diameter | Drill Point | Major Diameter | Minor Diameter | Head Diameter | Nominal Tensile | Minimum Torsional | Nominal Shear |

|---|---|---|---|---|---|---|---|

| #10 | #3 | .194 / .188 | .133 / .126 | .447 / .423 | 1550 lbs | 61 in-lbs | 1050 lbs |

| Pull Out Strength (LBS ULT) | ||||

|---|---|---|---|---|

| Material | ||||

| Designation | HRS Primed Only | |||

| Nom. Gauge | 12 | 14 | 16 | |

| Thickness | .105 | .075 | .060 | |

| #10 | 1271 | 1032 | 723 | |

QuikDrill Metal2Metal ClipScrews Specs

Our QuikDrill

Metal2Metal ClipScrews are designed to attach standing-seam roof clips to

steel purlins or frames. The special low-profile design features pancake

heads and a deep thread that pulls the fastener tighter and resists pull

out. As a result, you won’t get the dimpled roof panels and loose panel

problems typically caused by regular profile heads that don’t fasten tight.

Like all Marco ClipScrews, our QuikDrill Metal2Metal ClipScrews come

standard with 8-micron electroplating for exceptional lubricity, wear

resistance, and excellent durability.

| Size | Head | Carton Qty | Weight/M |

|---|---|---|---|

| 10 x 1″ | #2 Phillips Square Pancake | 5000 | 7.38 |

| 10 x 1-1/2″ | #2 Phillips SquarePancake | 2500 | 10.03 |

| 10 x 2″ | #2 Phillips SquarePancake | 2000 | 15.45 |

| Point Diameter | Drill Point | Major Diameter | Minor Diameter | Head Diameter | Nominal Tensile | Minimum Torsional | Nominal Shear |

|---|---|---|---|---|---|---|---|

| #10 | #3 | .194 / .188 | .133 / .126 | .447 / .423 | 1550 lbs | 61 in-lbs | 1050 lbs |

| Pull Out Strength (LBS ULT) | ||||

|---|---|---|---|---|

| Material | ||||

| Designation | HRS Primed Only | |||

| Nom. Gauge | 12 | 14 | 16 | |

| Thickness | .105 | .075 | .060 | |

| #10 | 1271 | 1032 | 723 | |

Installation Tip

Always choose the appropriate fastener for the thickness and type of material to be drilled for any given application. To ensure optimum fastening performance, a 1900 to 2500 RPM screw gun rated 6 amps or more and fitted with a properly adjusted depth-locating nosepiece should be used. Sufficient pressure must be applied while screw gun is perpendicular to the working area. Overdriving fasteners can lead to leaks and other problems.

A lobe socket grips the fastener on 6 sides to prevent paint chipping, which leads to rust. The nosepiece of the drill needs to be set to the correct height for proper washer installation.

Correct:

Drive fastener level to metal surface.

Incorrect:

Fastener not level with metal surface.